Application-specific cleaning concepts by Horpovel® GmbH

Good cleaning is result-oriented, cost-effective, reproducible and achieves a stable result. For this reason, Horpovel® GmbH has developed application-specific cleaning concepts (hereinafter referred to as Horpovel® AR concepts) for its customers. These concepts are used both in general CIP cleaning and in membrane cleaning.

Based on operational conditions, Horpovel® AR concepts can include not only an adjustment of temperature, time and concentration levels, but also the revision of the chemical component in terms of ingredients and set-up of the cleaning process.

Figure 1: requirements to be considered during cleaning

Figure 1: requirements to be considered during cleaning

The dual-component verification employed by Horpovel® and the use of the Horpovel® additive system (see technical article on www.horpovel.de/press/), the appropriate cleaning concept can be found and applied specifically to the respective process and the existing conditions.

Extensive experience of Horpovel® has shown that only an adaptation to the respective process and the specific conditions brings the best cleaning result. Thus, generalised cleaning concepts cannot achieve such a high level of effectiveness.

Horpovel® AR - concepts make it possible to work in a resource-saving and reproducible way. Especially in the field of membrane cleaning, the core competence of Horpovel® GmbH, the AR - concepts are a successful way of working.

In the field of membrane cleaning, this means an intensive examination of the current cleaning procedure by our experienced application engineers with subsequent target definition for the creation of the new cleaning concept.

With a variety of technical devices, it is possible to obtain a meaningful database of the existing system and, on its basis, to develop an appropriate concept adaptation.

Since filtration membranes change during their life cycle, this cleaning concept is continuously adapted and optimised by Horpovel® application technology.

Selection and design of the right sequence of cleaning steps

For all membrane cleaning, the cleaning must be based on the processed product and the local conditions. This information is used in process analysis to work out which cleaning steps are sensible and necessary. In addition to the sole cleaning effect of a step, the set-up of the membrane and microbiology also must be considered.

Based on experience gained from the AquaECON® concept developed with ALPMA/LTH Dresden, a new approach to rinsing optimisation in membrane plants was derived. In conjunction with an advanced chemical-physical process analysis of the cleaning by Horpovel®, rinsing phases can thus be significantly shortened to save resources.

In addition to the optimal sequence of steps, significant savings potential must be considered in choosing the exact parameters of circulation and rinsing. By adjusting the circulation steps, reductions in chemical dosing of up to 5% and more are possible. The intermediate rinsing steps adapted to the Horpovel® concepts generate reductions of up to 20% and more over conventional rinsing steps.

Enzymatic cleaning steps often are very important for successful cleaning. For enzymatic cleaning to be effective, optimal timing is essential. If the plant is not optimally prepared, it can happen that the enzymes do not act at the intended target locations of the plant. Rather, the most effective time should be determined through process analysis.

As part of process analysis, step times are optimised based on chemical-physical parameters. In addition, energy consumption is reduced by effective parameterisation of the steps.

In addition to adaptation of cleaning steps, significant potential results from observing the right cleaning chemistry. In addition to residue analysis in membrane autopsy, processing of technical conditions and requirements should be mentioned.

Depending on the membranes in use and their requirements, it is crucial to consider the accuracy and speed of dosing. If the conditions are right, the implementation of the Horpovel® additive system can bring decisive cost advantages.

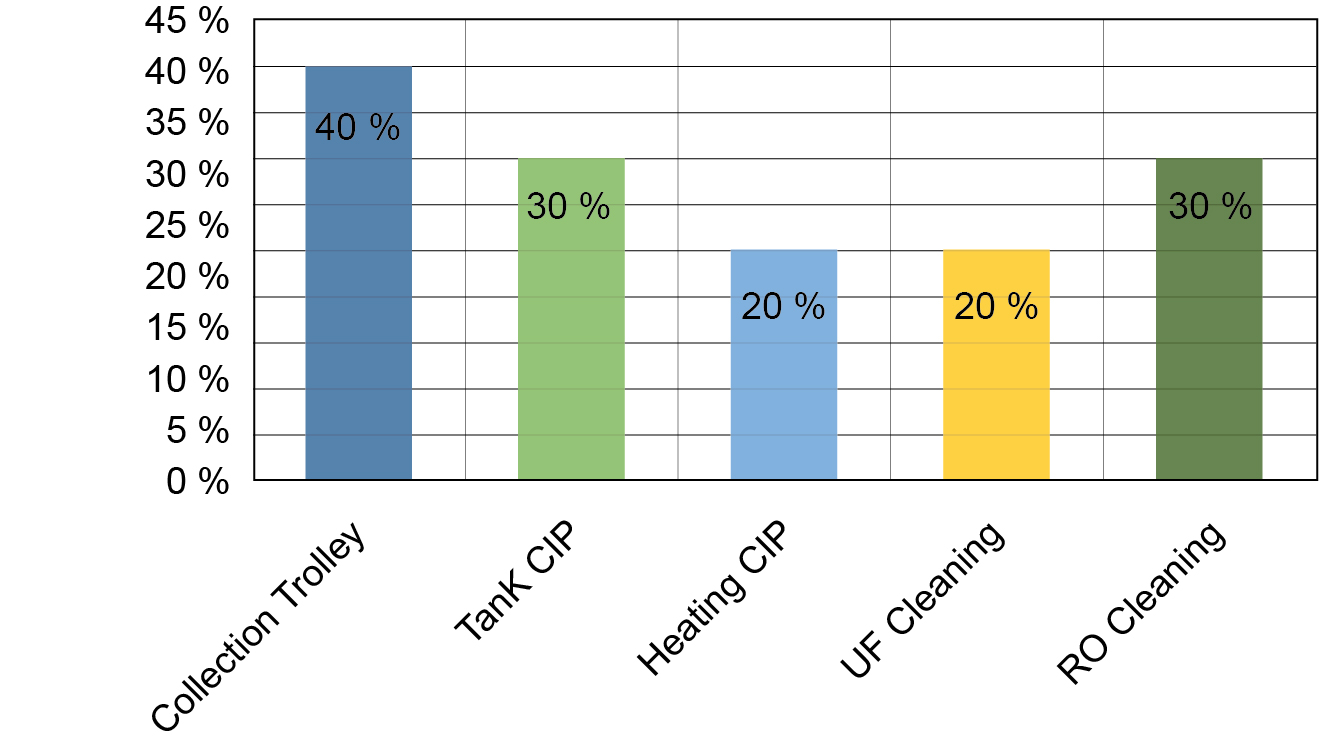

Figure 2: Possible reduction potential of chemicals when using the Horpovel® additive system of up to 40% compared to full assembly

Since filtration membranes are subject to a natural ageing process and the processes in the food industry are subject to fluctuations, the most important focus of Horpovel® GmbH is to provide customers with permanent, reliable and close-meshed advice and support with regard to cleaning and the cleaning results achieved, both on site and with online tools such as Horpovel® Live-View and online data loggers.

The Horpovel® service concept, provides regular control and monitoring of cleaning based on recorded chemical-physical parameters and ensures that deviations are detected at an early stage with possible adjustments to the process.

In addition to the biodegradability of the surfactants used, Horpovel® has reduced the use of EDTA to a minimum. This reduction is feasible due to targeted dosing of individual components in conjunction with the Horpovel® additive concept.

The acid cleaning concepts of Horpovel® offer the possibility of phosphoric acid-free cleaning (see technical article on www.horpovel.de/press/) and significantly reduce wastewater pollution by using new KOCHKLEEN™ products.

For both membrane cleaning and general CIP cleaning, the main components of the cleaning chemicals, caustic soda and nitric acid, can be purchased from local chemicals dealers. This simplifies the evaluation of current price structures and cost-effective buying of these components.

Horpovel® GmbH sees itself not only as a manufacturer and supplier of cleaning agents and disinfectants, but also as a service provider in the field of cleaning and disinfection. Thereby, an efficient and sustainable use of the available resources is in the focus of the optimization of cleaning processes. In collaboration with our cooperation partners and the use of KOCHKLEEN™ - membrane cleaning agents we continuously try to approach this goal.

*KOCHKLEEN is a registered trademark of Koch Separation Solutions, Inc. in the United States and may be registered in other jurisdictions.